Giải pháp

Tin tức

xem thêm >188 máy tính công nghiệp NISE3800E và NISE3900E triển khai trong ứng dụng chuyên dụng

Máy tính công nghiệp lắp đặt trên các phương tiện...

Tích hợp máy tính chuyên dụng trong hệ thống giám sát trạm quạt thông gió ở hầm lò khai thác than

Hiện nay, nhiều mỏ than hầm lò ở Việt Nam...

Máy tính công nghiệp có quạt có thực sự lọc được hết bụi với thiết kế AirFilters?

Máy tính công nghiệp có quạt là thuật ngữ dùng...

Giải pháp demo

xem thêm >

Mạng mở rộng 5G cấp độ nhà khai thác

NEXCOM bắt tay vào sự phát triển các giải pháp...

DCS Controller

NEXCOM PC-based DCS deployed across control environments by world-class petrochemical manufacturers.

More Intelligent, More Efficient

Manufacturers face evermore competitive pressures and threats. Every penny of extra cost must be cut and every ounce of efficiency must be extracted a plant in order to remain competitive.

To that end, one of NEXCOM's customers examined its smartly tuned network of 300+ factories and plants and asked the question: Where can we save? Their answer surprised everyone: a distributed control system (DCS) with Intel Inside®. The DCS is widely used around the world for process automation applications. However, for smooth operations, long-term maintenance, and minimum disruptions of obsolescence, an Intel processor-based DCS solution was selected with the aim of cutting total cost of ownership (TCO) and boosting operational efficiency.

The customer discerned the inefficiencies in its proprietary DCS system, and addressed its uncertain product cycle and high-inventory risks. The customer began an overhaul of its DCS strategy, which involved the development of a custom solution built on non-custom Intel processor-based parts. The customer expects to realize substantial TCO reductions as a result, along with a significant boost to both operational and maintenance efficiency when all new systems are fully deployed.

Open Architecture, Less Maintenance Cost

This project involves a large, world-class petrochemical manufacturer with more than 300 plants dispersed around the globe. To ensure smooth operation of large-scale facilities including oil refineries, steel mills, petrochemical factories, and power plants, the company used as many as 26 different brands of DCS systems to address the varying requirements of different control environments.

While this approach provided the needed versatility for its many different plant types, it was highly inefficient a maintenance and operational standpoint and also carried a high TCO. An extensive inventory of spare parts and a wide-scale investment in knowing how to maintain these systems only added to operational cost and complexity. Company leaders surmised that a standardized solution, such as an Intel® architecture-based system, could eliminate much of this overhead and boost overall competitiveness by leveraging its in-house customization capability.

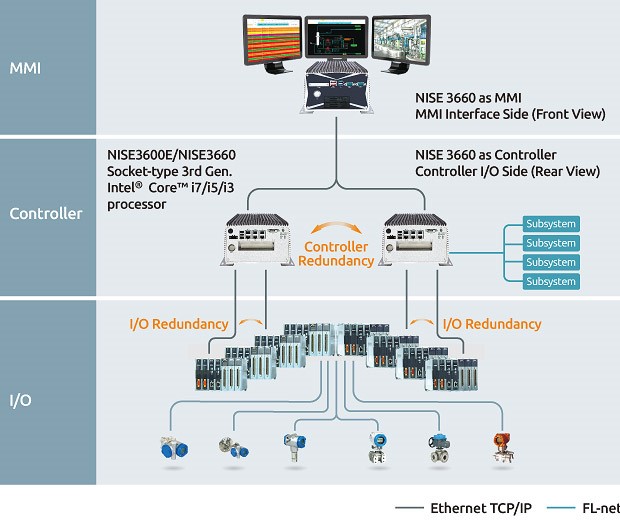

NISE in DCS Solution

The standardized DCS solution under discussion is composed of several subsystems. Each is made up of multiple units, and all can use the unified hardware platform that was developed in collaboration with NEXCOM. The unified hardware platform itself comprises multiple Intel® processor-based components, including an industrial PC and NEXCOM's NISE 3660, which plays two roles simultaneously: redundancy controller and man-machine interface (MMI). This DCS solution works across multiple control processes, including power generation, cogeneration processes, and midstream and downstream processes (see figure 1).

Best Choice NISE/NIFE Controller

NEXCOM is chosen for multiple reasons, including previous favorable experiences with an earlier generation NEXCOM MMI system. Plus, NEXCOM is one of the only industrial PC companies with DCS expertise, including domain knowledge in DCS architecture hardware design. This expertise, coupled with a long track record of developing fanless PC-based controllers and panel computers for automation environments around the globe, gave NEXCOM the winning edge for this project.

NEXCOM's NISE 3660 is equipped with all the functional interfaces required by both redundancy controller and MMI applications and can be used as one or the other depending on the need. Also, the controller-specific interfaces and MMI-specific interfaces are on two different sides of the NISE 3660. This differs most currently available, single-purpose controllers or MMI products that require companies to maintain inventories of both items.

Figure 1. NEXCOM NISE 3660 is installed in the cabinet as a DCS controller.

For use as a redundancy controller, the NISE 3660 runs a real-time operating system to perform reliable control schemes and Microsoft Windows® for use as an MMI that delivers high-resolution graphics.

The DCS controller provides controller redundancy and I/O redundancy as illustrated below. Every active controller is connected to a backup controller with two LANs. The DCS controller also supports Fieldbus technology to connect to PLCs and remote I/Os. For instance, PROFIBUS compatibility has been tested and certified by the customer (see figure 2).

Figure 2. NEXCOM NISE 3660 as deployed in the customer's DCS

Multi-Core Computing and Scalable Processor Intel

Intel processor-based components are favored in their new DCS design because they deliver performance, long-life support, generational compatibility, and scalability. For example, multicore Intel® processors can perform multiple jobs simultaneously, replacing several legacy processors and improving the overall cost/performance (C/P) value of the solution.

Value-added Service NEXCOM

The completed project is expected to yield significant gains in factory and plant efficiency, while dramatically cutting TCO through the adoption of a new Intel® architecture-based DCS system.

According to the DCS solution project manager, replacing legacy application-specific integrated circuits (ASIC) with x86 architecture allows the company to deliver products just in time and to cut inventory overhead costs by about 20 percent. Moreover, it reduces the effort of lifetime cycle maintenance and mitigates the risk of obsolete hardware components by about 15 percent to 30 percent. Also, the fanless NISE 3660 consumes little power and helps reduce energy by 40 percent compared to the legacy MMI.

NHÀ PHÂN PHỐI

NHÀ PHÂN PHỐI